Other categories:

Home » Our Products » Defoamers - Coatings & Inks

Defoamers - Coatings & Inks / Industrial & Metal working

Foamstop™

The Foamstop™ range offers foam control agents that include water- and oil-soluble and VOC-free products that can be used in many applications, for example: VOC-free emulsion systems based on PVAC and acrylics, curtain coatings, emulsion paints, metal working fluids, cleaners, and water-based systems.

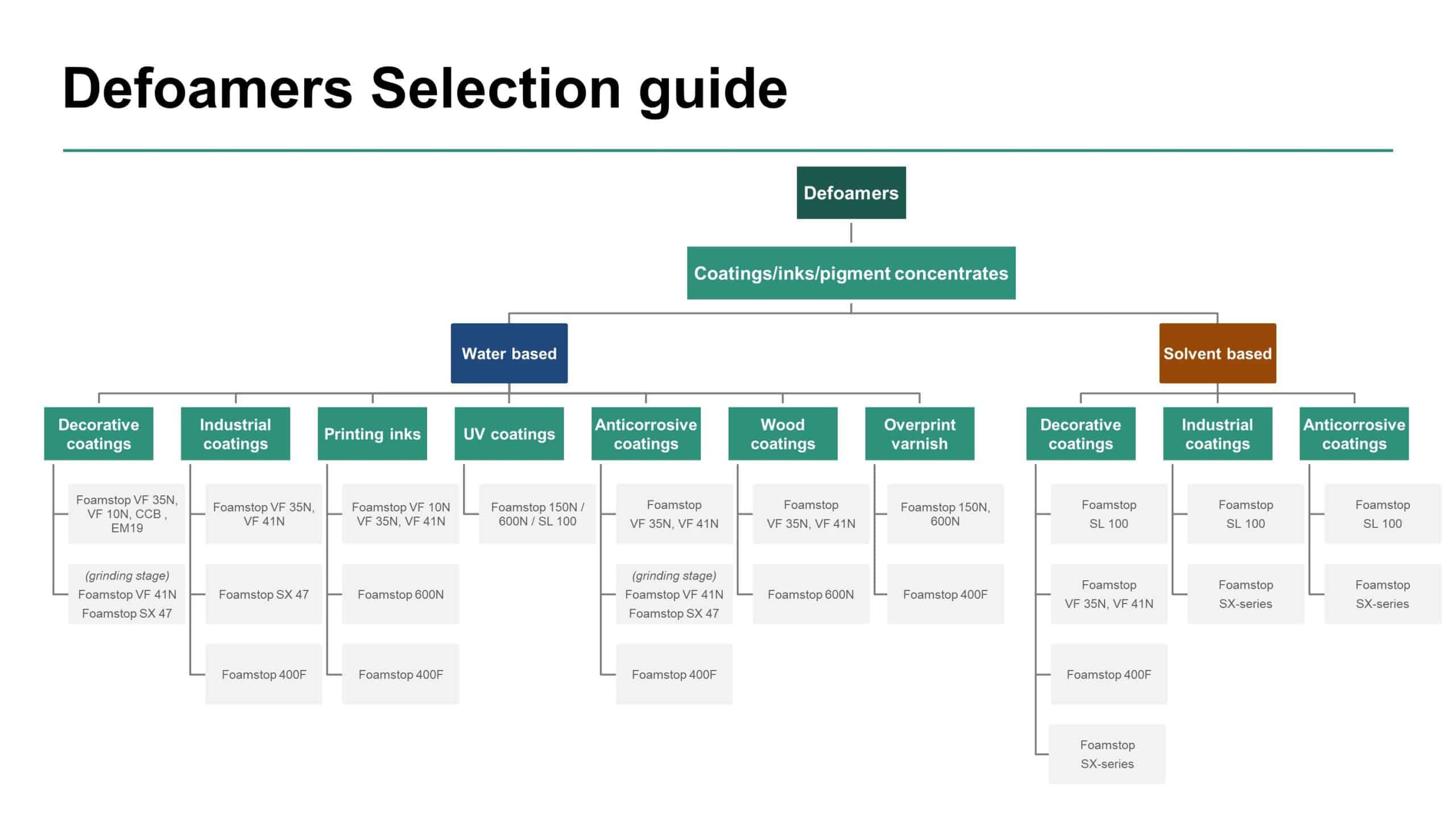

For additional information about defoamers for the coating industry please refer to the "Foamstop application table" or the "Foamstop selection guide" below.

Foamstop™ EM 19 is a cost-effective and sustainable foam control agent emulsion.

Emulsion of surface-active components and vegetable oils in water (>80% based on renewable resources).

Benefits

- Enhances gloss in certain emulsion-based paint systems due to improved levelling

- Suitable for emulsion paints, high gloss emulsions paints, and also for emulsion-based plasters

- Does not contain hydrocarbons, nonylphenol derivatives, silicones/siloxanes, amines, nitrates and fluorides

- Maintains the defoaming properties over a prolonged period of time

- Cost-effective

- Easy to incorporate

- Biobased carbon content of 85%

- Readily biodegradable

- VOC-free

Applications

- Paint industry

- Adhesive industry

- Floor polish industry

- Wastewater treatment

Foamstop™ CCB is a cost-effective foam control agent for emulsion systems based on PVAC, VA/VeoVa, styrene-acrylics or pure acrylics. It is biodegradable and has a high sustainable content.

Proprietary blend of PAGs and surface-active compounds, largely based on renewable resources.

Benefits

- Suitable for use in pigmented emulsion paints, printing inks as well as emulsion-based adhesives

- Very suitable for cost-effective, high PVC emulsion paints

- Does not contain hydrocarbons, nonylphenol derivatives, silicones/siloxanes, amines, nitrates and fluorides.

- Maintains the defoaming properties over a prolonged period of time

- Biobased carbon content of 90%

- Readily biodegradable

- VOC-free

Applications

- Paint industry

- Adhesive industry

- Floor polish industry

- Wastewater treatment

Foamstop™ VF 41N is a highly efficient all-round foam control agent. It is VOC; silicone/siloxane-free, specially developed for optimum foam control in the grinding process of (resin-free) pigments and fillers.

Proprietary blend of vegetable oil with PAGs and surface-active components.

Benefits

- High performance in high shear dispersing processes

- Shows good performance in combination with ADDISP™ ECO and BioFlow™ 71 in the production of (resin-free) universal pigment concentrates

- Recommended for thick, highly viscous film applications in both solvent-based systems (deaerator) and water-based systems (defoamer/deaerator)

- It provides high transparency and no haze in both solvent-based and water-based clear lacquers

- Maintains the defoaming properties over a prolonged period of time

- Does not contain nonylphenol derivatives (APEO-free); silicones/siloxanes; amines; nitrates or fluorides

- Excellent deaerating in pigment grinding

- Biobased carbon content of 39%

- Readily biodegradable

- VOC-free

Applications

- (Resin-free) pigment concentrates

- Paints and plasters

- Inks (flexo inks, OPV)

- Adhesives

Foamstop™ VF 10N is an effective and sustainable foam control agent recommended for use in pigmented low-VOC emulsion paints, (flexo-) printing inks as well as emulsion-based adhesives.

Proprietary blend of components largely based on renewable resources.

Benefits

- Very suitable for cost-effective, high PVC emulsion paints, textured masonry coatings and renders/plasters (putz)

- Maintains the defoaming properties over a prolonged period of time

- Disperses easily, requiring only mild agitation

- Does not contain nonylphenol derivatives (APEO-free); silicones/siloxanes; amines; nitrates or fluorides

- Biobased carbon content of 91%

- Readily biodegradable

- ECO-label compliant

- VOC-free

Applications

- (Flexo-) printing inks

- Paint industry

- Adhesive industry

- Floor polish industry

- Lubricant industry

- Wastewater treatment

Foamstop™ VF 35N is a highly effective and sustainable foam control agent for both water- and solvent-based (coating) systems. Superior alternative to mineral oil-based defoamers.

Proprietary blend of oils with PAGs and surface-active components.

Benefits

- Very suitable for high PVC emulsion paints and low VOC emulsion paints based on PVAC, styrene/acrylics or pure acrylics

- Very suitable for cost-effective, high PVC emulsion paints

- Maintains the defoaming properties over a prolonged period of time

- Disperses easily, requiring only mild agitation

- Does not contain nonylphenol derivatives (APEO-free); silicones/siloxanes; amines; nitrates or fluorides

- Biobased carbon content of 72%

- Readily biodegradable

- ECO-label compliant

- VOC-free

Applications

- Paint and plaster industry

- Adhesive industry

- Lubricant industry

- Wastewater treatment

Foamstop™ 100N is a water-soluble defoamer that is used in the paint and printing ink industry. Gives no turbidity or haze and no paint or plating adhesion problems and maintains the defoaming properties.

Proprietary blend of polyalkylene glycols and surface-active components.

Benefits

- Fully soluble in water; no turbidity or haze of the liquid phase in clear systems

- Maintains the defoaming properties over a prolonged period of time

- Effective over a wide pH range (2 to 12)

- Does not contain mineral oil, amines, nitrates or fluorides

- Biodegradable

Applications

- Paint and lacquer industry

- Printing ink industry

- Floor polish- and cleaner industry

- Aqueous hydraulic fluids

- Aqueous metalworking fluids

Foamstop™ 150N acts as a highly effective, water-soluble foam control agent. Gives no turbidity or haze of the liquid phase in clear systems and no paint or plating adhesion problems. Used for all types of aqueous systems especially curtain coating- and spray applications for paint and printing ink industries.

Proprietary blend of polyacrylates, PAGs and surface-active components.

Benefits

- Fully soluble in water; no turbidity or haze of the liquid phase in clear systems

- Maintains the defoaming properties over a prolonged period of time

- Effective over a wide pH range (6 to 12)

- Does not contain mineral oil, amines, nitrates or fluorides

- Biodegradable

Applications

- Paint and lacquer industry

- Printing ink industry

- Floor polish- and cleaner industry

- Aqueous hydraulic fluids

- Aqueous metalworking fluids

- Galvanic baths

Foamstop™ 400F acts as a water-soluble foam control agent. Gives no turbidity or haze of the liquid phase in clear systems and maintains the defoaming properties over a prolonged period of time. Also suitable for a wide range of solvent-borne systems.

Proprietary blend of polyalkylene glycols and surface-active components.

Benefits

- Emulsifiable in water; no haze of the liquid phase in clear systems

- Good compatibility with a wide range of solvent-borne systems.

- Maintains the defoaming properties over a prolonged period of time

- Effective over a wide pH range (0 to 14)

Applications

- Paint and lacquer industry

- Printing ink industry

- Solvent-based systems

- Floor polish- and cleaner industry

- Aqueous metalworking fluids

Foamstop™ 400N is a highly effective foam control agent used in aqueous systems with

extreme pH values for paint and printing ink industries. Gives no turbidity or haze and no paint or plating adhesion problems.

Proprietary blend of polyalkylene glycols and surface-active components.

Benefits

- Fully soluble in water; no turbidity or haze of the liquid phase in clear systems

- Maintains the defoaming properties over a prolonged period of time

- Effective over a wide pH range (0 to 14)

- Biodegradable

Applications

- Paint and lacquer industry

- Printing ink industry

- Floor polish industry

- Aqueous hydraulic fluids

- Aqueous metalworking fluids

- Cleaners

- Acidic media

Foamstop™ 600N is a defoaming agent used in the paint and printing ink industries. It gives no turbidity or haze and no paint or plating adhesion problems.

Blend of polyalkylene glycols and surface-active components.

Benefits

- Fully soluble in water; no turbidity or haze of the liquid phase in clear systems

- Maintains the defoaming properties over a prolonged period of time

- Effective over a wide pH range (2 to 12)

- Biodegradable

- Does not contain mineral oil, amines, nitrates or fluorides

Applications

- Paint and lacquer industry

- Printing ink industry

- Floor polish and cleaner industry

- Aqueous hydraulic fluids

- Aqueous metalworking fluids

Foamstop 666V is a water-soluble foam control agent.

Proprietary blend of polyalkylene glycols and surface-active components.

Benefits

- Fully soluble in water; no turbidity or haze of the liquid phase in clear systems

- High-temperature range (40 - 75 °C)

- Maintains the defoaming properties over a prolonged period of time

- Effective over a wide pH range (2 to 12)

- Biodegradable

- Does not contain mineral oil, amines, nitrates or fluorides

Applications

- Paint industry

- Printing ink industry

- Stearates industry

- Floor polish and cleaner industry (high-temperature range)

- Aqueous hydraulic fluids

- Aqueous metalworking fluids

Foamstop™ WS 17 is a highly effective and completely water-soluble foam control agent. 100% soluble in water, with no turbidity or haze of the liquid phase in clear systems.

Proprietary blend of polyalkylene glycols and surface-active components.

Benefits

- Fully soluble in water; no turbidity or haze of the liquid phase in clear systems

- Designed for aqueous systems with extreme pH values (1 - 13)

- Maintains the defoaming properties over a prolonged period of time

- Does not block filters and spray nozzles

- Metal surfaces are readily cleaned by rinsing with tap water

- Biodegradable

Applications

- Aqueous metalworking fluids

- Paint industry

- Printing ink industry (Flexo)

- Floor polish and cleaner industry

- Aqueous hydraulic fluids

- Acidic and alkaline media

Foamstop™ SL 10 is a highly effective and versatile foam control agent emulsion. It is extremely stable both in storage and in the final system.

10% active silicone emulsion containing minerals and fatty acid-based emulsifiers.

Benefits

- Very rapid defoaming effect under static conditions

- Disperses easily, requiring only mild agitation

- Maintains the defoaming properties over a prolonged period of time

Applications

- Paint industry

- Printing ink industry

- Adhesives and glues

- Sewage and effluent treatment

- Boiler washing

- Cutting fluids

- Fertiliser manufacturing

Foamstop™ SL 30 is a highly effective and versatile foam control agent emulsion. It is extremely stable both in storage and in the final system.

30% active silicone emulsion containing minerals and fatty acid-based emulsifiers.

Benefits

- Very rapid defoaming effect under static conditions

- Disperses easily, requiring only mild agitation

- Maintains the defoaming properties over a prolonged period of time

Applications

- Paint industry

- Printing ink industry

- Adhesives and glues

- Sewage and effluent treatment

- Boiler washing

- Cutting fluids

- Fertiliser manufacturing

Foamstop™ SL 100 is a concentrated and versatile silicone foam control agent. It can be used in both aqueous and non-aqueous systems. Maintains its defoaming properties.

100% active silicone compound containing minerals.

Benefits

- Maintains the defoaming properties over a prolonged period of time

- Disperses easily, requiring only mild agitation

Applications

- Paint industry

- Printing ink industry

- Cutting oils

- Epoxy resin systems

Foamstop™ SX 31 is a highly effective siloxane-based, foam control agent for all types of aqueous and non-aqueous metalworking lubricant concentrates based on polyoxyalkylene technology and cleaners.

Proprietary blend of siloxane-based surface-active components, 100% active.

Benefits

- Shows a very rapid defoaming effect under static conditions

- Maintains the defoaming properties over a prolonged period of time

- Disperses easily, requiring only mild agitation

- Effective over a wide pH range (2 - 12)

Applications

- Lubricant industry

- Textile industry

- Solvent-based coatings

- Cleaners

Foamstop™ SX 47 is a highly effective foam control agent for all types of aqueous and non-aqueous metalworking systems and cleaners. Effective defoaming agent for use in the pigment grinding stage of both water- and solvent-based pigment concentrates.

Blend of polyalkylene glycols, siloxane and surface-active components.

Benefits

- Shows a very rapid defoaming effect under static conditions

- Washable under typical industrial cleaning and rinsing practices and consequently subsequent painting after washing without defects

- Maintains the defoaming properties over a prolonged period of time

- Disperses easily, requiring only mild agitation

- Excellent defoamer for the production of PVC

- Effective over a wide pH range (0 - 14)

Applications

- (Universal) pigment concentrates

- Solvent-based coatings

- Lubricant industry

- PVC production

- Industrial cleaners

Foamstop™ SX 53 is a highly effective and concentrated foam control agent for all types of aqueous and non-aqueous systems. Suitable for e.g. cleaners, textiles and lubricants.

Proprietary blend of siloxane-based surface-active components, 100% active.

Benefits

- Shows a very rapid defoaming effect under static conditions

- Maintains the defoaming properties over a prolonged period of time

- Effective over a wide pH range (0 - 14)

Applications

- Paint industry (solvent-based)

- Printing ink industry

- PVC production

- Textile industry

- Lubricant industry

- Cleaners

Foamstop™ SX 67 is a highly effective and compatible foam control agent for all types of aqueous and non-aqueous systems.

Proprietary blend of polyalkylene glycols and siloxane-based surface-active components, 100% active.

Benefits

- Shows a very rapid defoaming effect under static conditions

- Disperses easily, requiring only mild agitation

- Maintains the defoaming properties over a prolonged period of time

- Can be sterilised before use

- Effective over a wide pH range (0 - 14)

Applications

- Paint industry

- Printing ink industry

- PVC production

- Food processing industry

- Lubricant industry

Foamstop™ OPE 032 is a polymeric defoamer especially formulated for the production of paper, pulp as well as for the production of Eternit.

Blend of fatty alcohols and esters.

Benefits

- 100% active product and shows excellent performance in the control of foams and improves the flow and reduces the viscosity of the medium

- Leaves no residues in the pipes or valves of the equipment used

- Inherently biodegradable and non-toxic to aquatic life

- ECO-label compliant

- VOC-free

Applications

- Paper industry

- Eternit production

Sign Up for

Our Newsletter

Subscribe to us to always stay in touch with us and get the latest news

about our company and all of our activities!