Other categories

Home » Our Products » Adhesion Promoters

Adhesion Promoters & Corrosion Inhibitors

VeoPox™

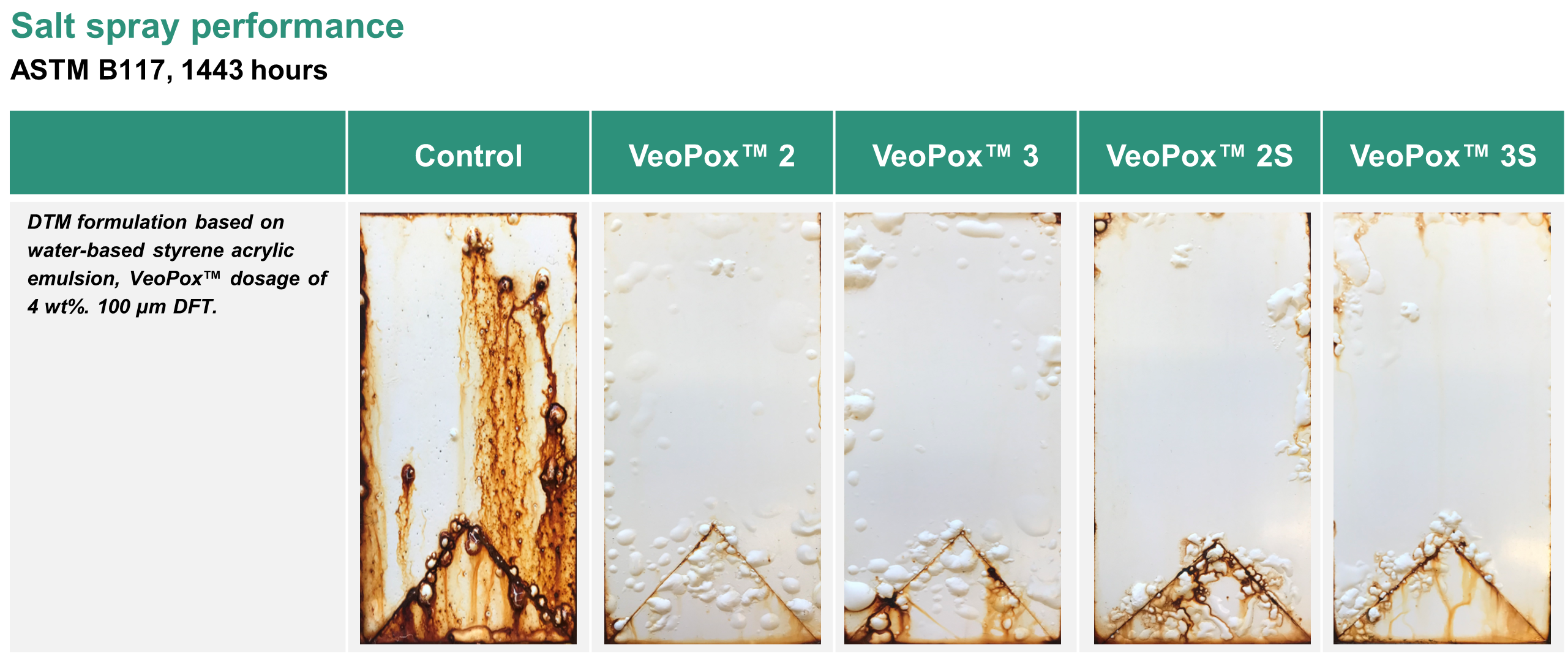

The VeoPox™ range is designed as novel adhesion promoters for formulators or resin manufacturers developing direct-to-metal (DTM) systems for light-, mid- and heavy-duty systems.

VeoPox™ systems are chemical hybrid systems based on combinations of epoxy, fatty acid and (meth)acrylates. The VeoPox™ range can be used as additives giving excellent adhesion and corrosion protection in systems like:

- Water-based DTM systems based on various types of binders, e.g., styrene-acrylic, alkyd, PU, etc.

- Solvent-based DTM systems/high solid/solvent-free systems cured by peroxide or driers.

- Solvent-free UV-curable DTM systems.

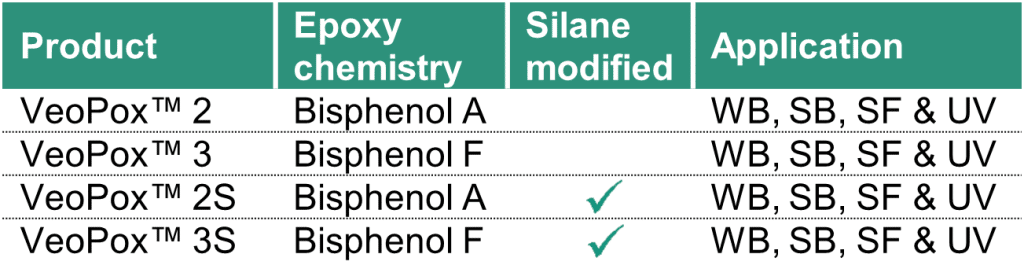

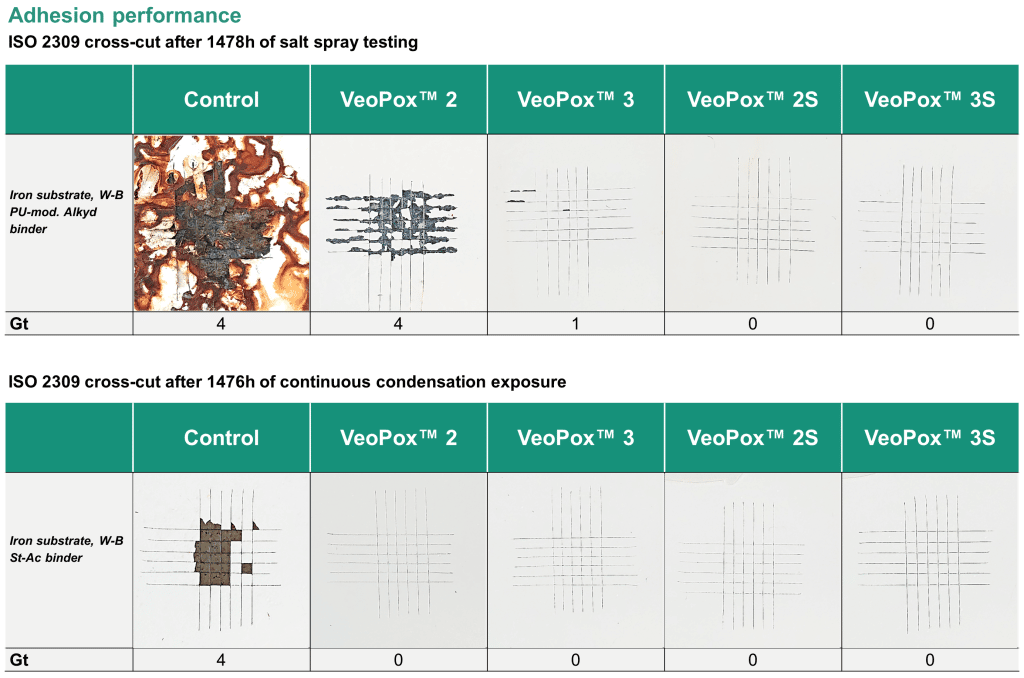

VeoPox™ 2 is a reactive hybrid precursor for direct-to-metal coatings and adhesive resin systems. It improves the adhesive and anti-corrosion properties of water- and solvent-based direct-to-metal coating systems. Significantly boosts the salt spray and condensation resistance of coatings.

Fatty acid-phosphate modified bisphenol A epoxy resin with reactive functionalities.

Benefits

- Excellent adhesion promoter for metal substrates

- Greatly increases anticorrosive properties and chemical resistance

- Suitable for water-based and solvent-based systems

- Polymerisable hybrid precursor

- Can replace anti-corrosive pigments like zinc phosphates

- Increases surface toughness

- Solvent-free (reactive dilutant, VeoVa 10)

- Biobased carbon content of 24%

Applications

- Water- & solvent-based direct-to-metal coatings

- UV curing systems

- 1- & 2-component adhesives

- Emulsion polymerisation

VeoPox™ 2S is a reactive hybrid precursor for direct-to-metal coatings and adhesive resin systems. It greatly improves the adhesive and anti-corrosion properties of water- and solvent-based direct-to-metal coating systems. Significantly boosts the salt spray and condensation resistance of coatings. It is the silane-modified version of VeoPox™ 2.

Fatty acid-phosphate modified bisphenol A epoxy resin with reactive functionalities and silane technology.

Benefits

- Excellent adhesion promoter for metal substrates

- Greatly increases anticorrosive properties and chemical resistance

- Suitable for water-based and solvent-based systems

- Polymerisable hybrid precursor

- Can replace anti-corrosive pigments like zinc phosphates

- Increases surface toughness

- Solvent-free (reactive dilutant, VeoVa 10)

- Biobased carbon content of 23%

Applications

- Water- & solvent-based direct-to-metal coatings

- UV curing systems

- 1- & 2-component adhesives

- Emulsion polymerisation

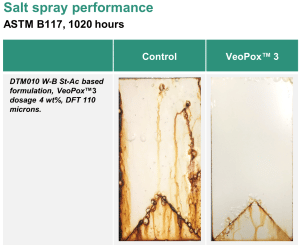

VeoPox™ 3 is a reactive hybrid precursor for direct-to-metal coatings and adhesive resin systems. It improves the adhesive and anti-corrosion properties of water- and solvent-based direct-to-metal coating systems. Significantly boosts the salt spray and condensation resistance of coatings.

Fatty acid-phosphate modified bisphenol F epoxy resin with reactive functionalities.

Benefits

- Excellent adhesion promoter for metal substrates

- Greatly increases anticorrosive properties and chemical resistance

- Suitable for water-based and solvent-based systems

- Polymerisable hybrid precursor

- Can replace anti-corrosive pigments like zinc phosphates

- Increases surface toughness

- Solvent-free (reactive dilutant, VeoVa 10)

- Biobased carbon content of 26%

Applications

- Water- & solvent-based direct-to-metal coatings

- UV curing systems

- 1- & 2-component adhesives

- Emulsion polymerisation

VeoPox™ 3S is a reactive hybrid precursor for direct-to-metal coatings and adhesive resin systems. It greatly improves the adhesive and anti-corrosion properties of water- and solvent-based direct-to-metal coating systems. Significantly boosts the salt spray and condensation resistance of coatings. It is the silane-modified version of VeoPox™ 3.

Fatty acid-phosphate modified bisphenol F epoxy resin with reactive functionalities and silane technology.

Benefits

- Excellent adhesion promoter for metal substrates

- Greatly increases anticorrosive properties and chemical resistance

- Suitable for water-based and solvent-based systems

- Polymerisable hybrid precursor

- Can replace anti-corrosive pigments like zinc phosphates

- Increases surface toughness

- Solvent-free (reactive dilutant, VeoVa 10)

- Biobased carbon content of 25%

Applications

- Water- & solvent-based direct-to-metal coatings

- UV curing systems

- 1- & 2-component adhesives

- Emulsion polymerisation

BioWet™ 60G is a solvent-free adhesion promoter and corrosion inhibitor for glass substrates. It is non-foaming and imparts anti-corrosion properties for ferrous and aluminium substrates. It allows flow regulation and shows wetting performance. Used in primers, gloss emulsion paints and printing inks. The recommended dosage for coatings is 0.05 - 1.5 wt.% based on total formulation and for printing inks 0.05 - 2.0% based on total formulation.

Proprietary blend of polyalkylene glycols and polyhydroxy amide.

Benefits

- Excellent adhesion promoter for glass substrates

- Offers resistance against glass corrosion in dishwashing applications

- Provides anti-corrosion properties for ferrous and aluminium substrates.

- Non-foaming

- Biobased carbon content of 80%

- Readily biodegradable

- Low VOC

Applications

- Coatings

- Printing inks

- Cleaning agents

Sign Up for

Our Newsletter

Subscribe to us to always stay in touch with us and get the latest news

about our company and all of our activities!