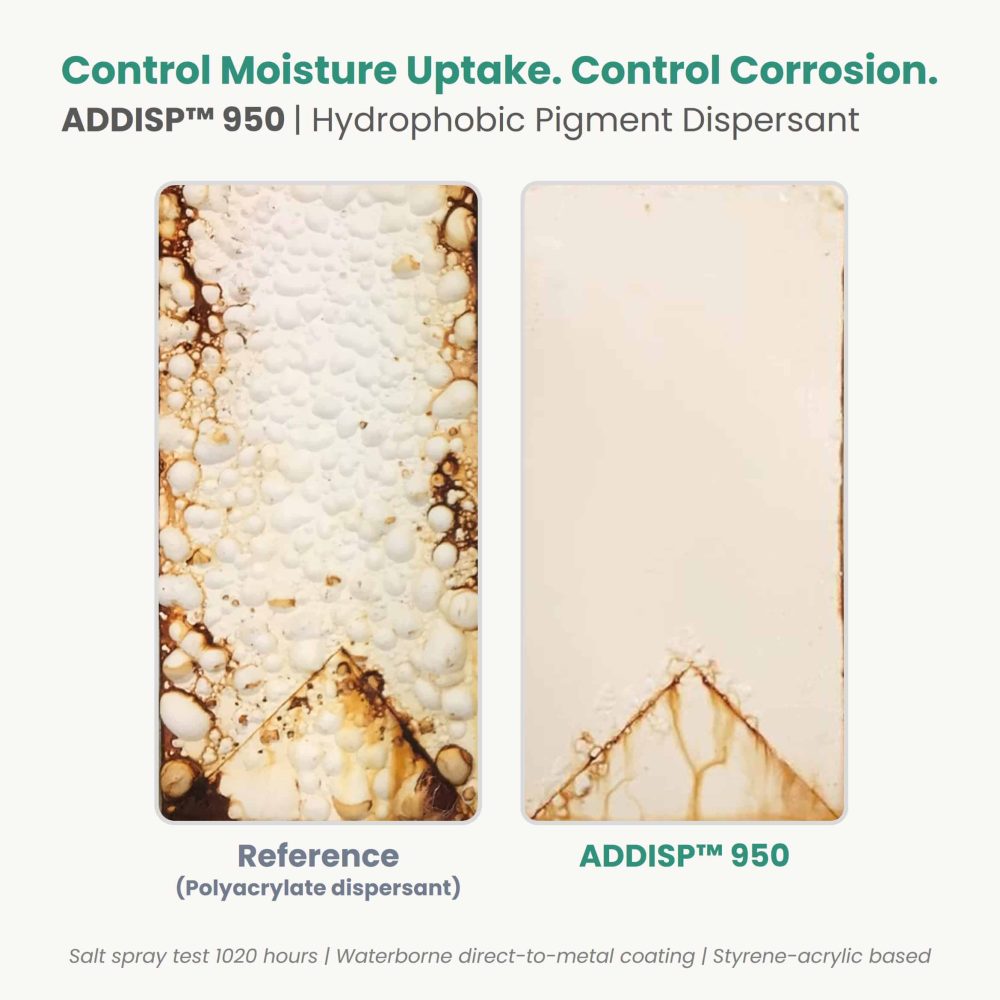

Other categories

Home » Our Products » Dispersing Agents

ADDISP™ 500N is an excellent solvent-free dispersing agent for (mineral) pigments and fillers. It enables a high pigment loading at a low viscosity.

Low- and narrow molecular weight polyacrylate dispersant having an ammonium cation, 37 - 40% solids.

ADDISP™ 550 is a VOC- and solvent-free, readily biodegradable wetting agent for pigments for aqueous systems and resin-free pigment concentrates. Highly recommended to use in combination with the ADDISP™ 850 dispersing agent.

Mixture of polymeric non-ionic surface-active components in water.

Benefits

- Biodegradable and sustainable additive

- Good wetting agent for a wide variety of pigments, i.e., inorganic/organic/etc.

- Provides additional wetting properties for carbon black pigments

- Biobased carbon content of 28%

- Readily biodegradable

- VOC-free

Applications

- Architectural coatings

- Decorative coatings

- Industrial coatings

ADDISP™ 600N is an excellent solvent-free dispersing agent for titanium dioxide, mineral pigments, and fillers. It is also excellently suitable for colourants and reactive pigments. It is recommended in formulations with medium-high PVC (30 - 80 %). In comparison with most dispersants, the abrasion values are significantly lower.

Very low- and narrow molecular weight polyacrylate dispersant containing phosphate moieties and having a sodium cation, 40% solids.

Benefits

- Excellent dispersants for titanium dioxide, minerals, and inorganic pigments

- Provides high wet scrub resistance, allows reduction of TiO2 and binder

- Hard water resistant due to phosphate moiety – use without polyphosphates!

- ECO-label compliant

- VOC & SVOC-free

Applications

- Titanium dioxide slurries

- Inorganic pigment and mineral concentrates

- Architectural coatings

- Decorative coatings

- Wood coatings

ADDISP™ 850 is a VOC- and solvent-free, readily biodegradable pigment dispersant for aqueous systems and resin-free pigment concentrates. Highly recommend using it in combination with the ADDISP™ 550 wetting agent. ADDISP™ 850 is non-foaming.

Amphoteric surface-active components in water.

Benefits

- Biodegradable and sustainable additive

- Good dispersing agent for a wide variety of pigments, i.e., inorganic/organic/etc.

- Provides additional wetting properties for carbon black pigments

- No ball mill needed

- Biobased carbon content of 75%

- Readily biodegradable

- ECO-label compliant

Applications

- Architectural coatings

- Decorative coatings

- Industrial coatings

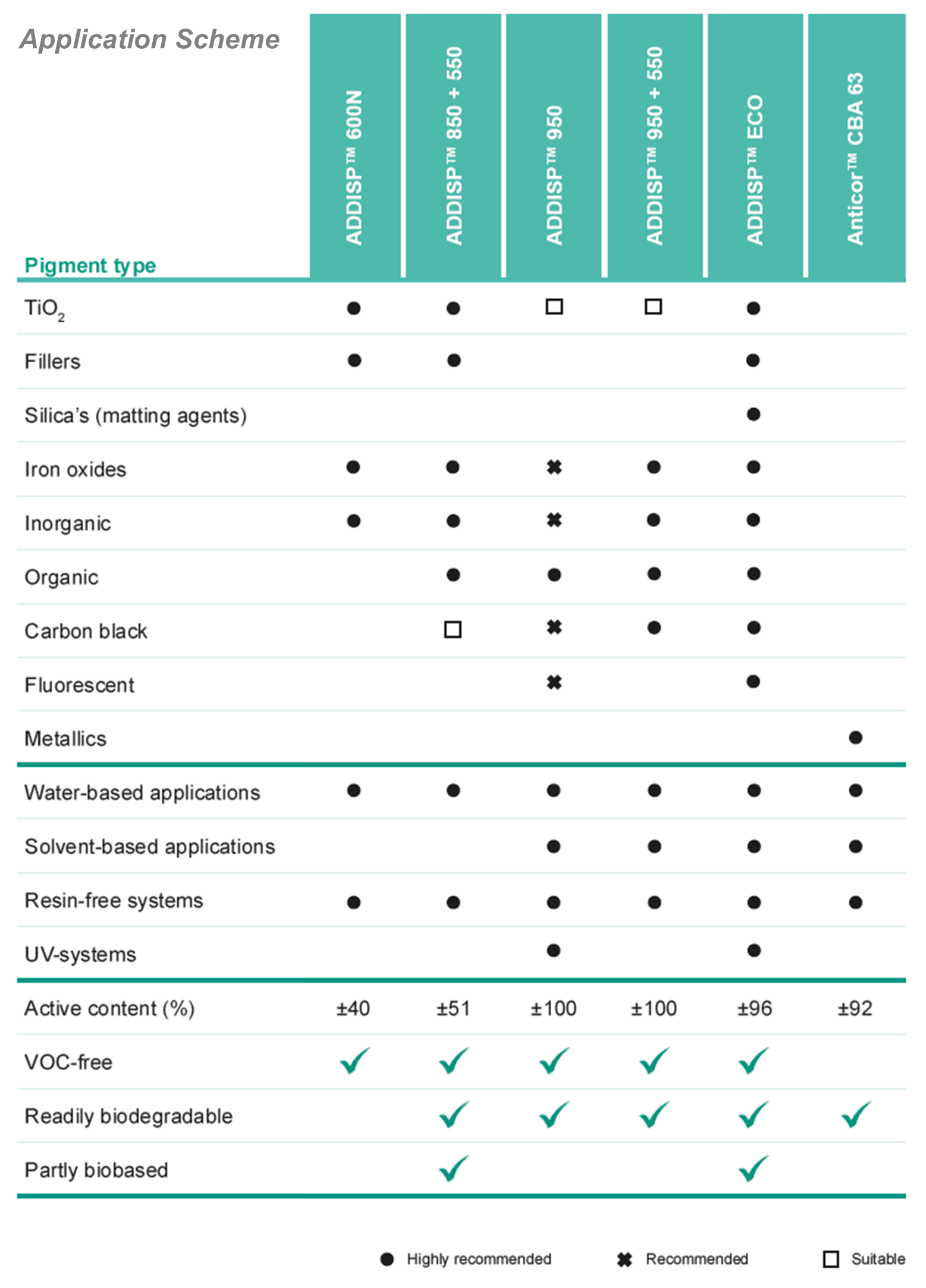

ADDISP™ 950 is an efficient and hydrophobic dispersing and wetting agent for VOC-compliant aqueous and non-aqueous systems. Universal dispersant for many types of pigments. It improves colour strength, reduces flocculation, flooding, and storage stability through steric stabilisation. Suitable for the preparation of universal pigment concentrates. Ideally suited for formulations where low water sensitivity is critical, including DTM, industrial, and marine coatings.

High molecular weight, non-ionic copolymer with pigment-affinic groups.

Benefits

- Universal dispersant for WB, SB, and UV systems

- Provides excellent colour development and tinting strength

- Low water sensitivity – hydrophobic nature

- No ball mill needed

- 100% active

- Readily biodegradable

- VOC-free

Applications

- Direct-to-metal coatings

- Industrial coatings

- Marine coatings

- UV-coatings

- Pigment concentrates and colourants

ADDISP™ ECO is a universal reactive pigment dispersing agent partially sourced from biomass. As a ‘One for All’ solution, ADDISP™ ECO excels in preparing organic and inorganic pigment concentrates with particle sizes below 5 microns by using only a dissolver."

Biobased polymer with surface-active components.

Click here for the ADDISP™ ECO technical leaflet & starting point formulations

Benefits

- No ball mill necessary, dissolver only

- One for all pigment dispersant

- Suitable for inorganic, organic, carbon black, and various fillers

- Suitable for water-, solvent & UV-based applications

- Reduction of manufacturing costs & waste

- Lower investment costs

- Biobased carbon content of 25%

- Readily biodegradable

- VOC-free

Applications

- UV coatings

- Water-based & solvent-based systems

- Anticorrosive coatings

- Industrial coatings

- Pigment concentrates/colourants & fillers

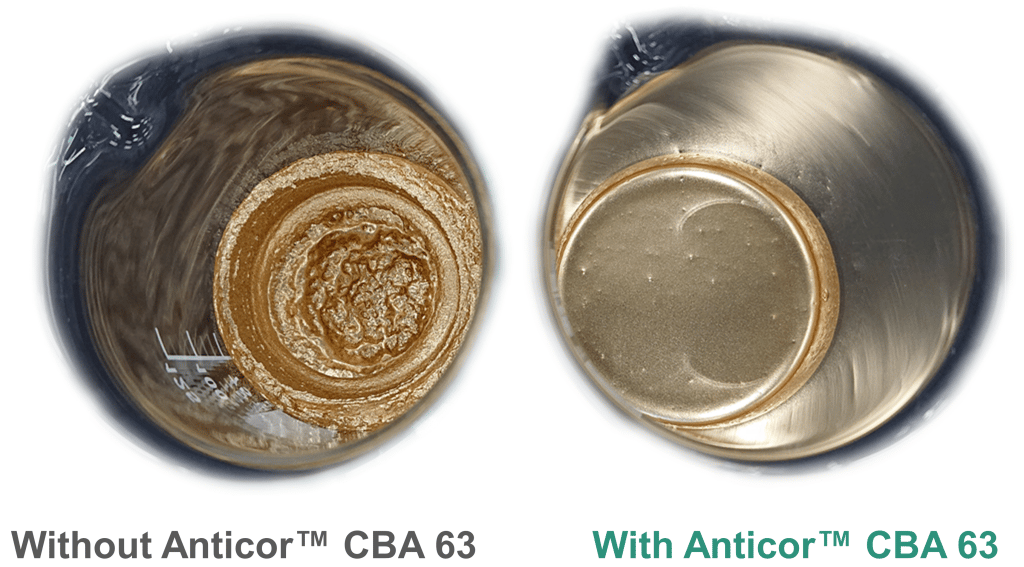

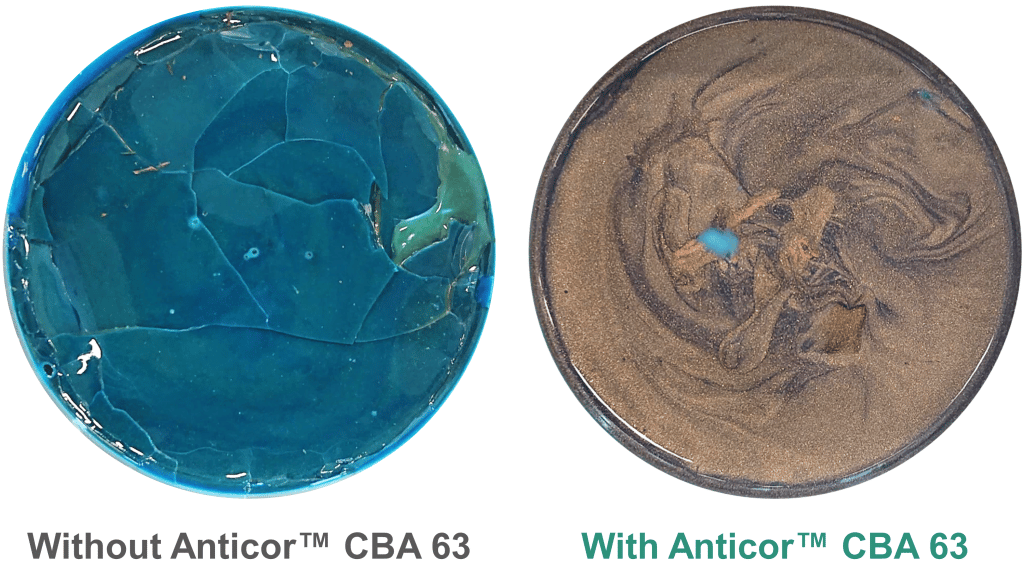

Anticor™ CBA 63 is an anti-corrosion/metal passivating additive for metallic pigments. It protects (unstabilised) copper, bronze and aluminium pigments from oxidation and gas formation reactions.

Proprietary blend of phosphonates and glycol ethers.

Benefits

- Greatly improves wetting and dispersing of metallic pigments

- Inhibits gas hydrogen gas formation during storage

- Prevents corrosion and skin formation during storage

- Passivates un-passivated aluminium and zinc pigments

- Protects metallic pigments from medium-high shear processing

- Increases production time

- Non-foaming

- Readily biodegradable

- ECO-label compliant

Applications

- Metallic pigment concentrates

- Metallic effect coatings

See also our YouTube channel for additional information about Anticor™ CBA 63 and others.

Sign Up for

Our Newsletter

Subscribe to us to always stay in touch with us and get the latest news

about our company and all of our activities!